Repairing a small speaker requires a systematic approach beginning with disconnection from power sources. First, diagnose the problem through visual inspection and listening tests. Gather necessary tools including screwdrivers, adhesives, and possibly a multimeter. Carefully remove the damaged driver, clean all components with isopropyl alcohol, and make necessary repairs to the cone or surround. Apply appropriate adhesive, allow 24 hours for proper curing, then reinstall and test at low volume. These straightforward steps can restore functionality to most damaged speakers.

Key Takeaways

- Assess damage by checking for buzzing, crackling, or visible issues like cone tears or detachment from the rubber surround.

- Gather necessary tools including screwdrivers, glue, and replacement parts that match your speaker’s specifications.

- Carefully disassemble the speaker by removing screws, disconnecting wires, and separating damaged components.

- Clean all surfaces with isopropyl alcohol on a lint-free cloth before applying appropriate adhesive to repair or replace parts.

- Allow adhesives to dry completely for 24 hours before reinstalling and testing the speaker at low volume.

Understanding Speaker Damage and Assessing Repair Needs

When a small speaker begins to fail, identifying the specific type of damage is the essential first step toward successful repair. A blown speaker typically exhibits distinct auditory symptoms, including buzzing, crackling, or hissing noises when volume is increased, indicating internal component failure such as voice coil damage or cone separation.

Physical inspection can reveal visible issues like punctures, warping, or detachment of the cone from its rubber surround. For thorough assessment, test the speaker by playing music at high volume levels (7-8 out of 10) while adjusting the equalizer to isolate specific frequency problems. Using diagnostic tools, such as a multimeter to check impedance, can confirm suspected issues before determining appropriate repair methods. When evaluating stereo systems, compare both speakers to identify potential imbalances that might indicate damage in one unit.

Additionally, evaluating the RMS power rating helps determine if the speaker was overloaded, as this indicates sustained performance capabilities to avoid distortion in home audio setups.

Gathering Tools and Materials for Speaker Repair

Before attempting any speaker repair project, a thorough collection of appropriate tools and materials must be assembled to guarantee successful outcomes. Basic tools required include a screwdriver for removing fasteners, a drill for making necessary adjustments, and a ruler for taking precise measurements throughout the repair process. A tape measure is essential for determining the exact diameter of the speaker driver, guaranteeing compatibility when selecting replacement components.

For adhesive applications in speaker repair, Gorilla Glue works effectively for bonding rubber surrounds, while rubber cement from bicycle repair kits provides flexibility when fixing plastic cones. Diagnostic equipment, particularly a multimeter, allows technicians to test impedance levels and identify electrical faults before proceeding. Finally, specialized materials such as recone kits or replacement drivers matching the original specifications in wattage and frequency response guarantee ideal sound reproduction after repairs.

Safely Removing the Damaged Driver

The safe removal of a damaged driver represents the critical first step in any speaker repair process, requiring methodical attention to both electrical safety and mechanical precision. Before attempting to remove the old driver, technicians must disconnect all wires from the power source to eliminate shock risks. Using an appropriate screwdriver, carefully loosen the guide screws around the driver’s perimeter while supporting the component with one hand to prevent accidental drops when the final screw is removed.

For the wire detachment phase, examine whether connections use quick-release clips or soldered joints, making note of any wiring that may need replacement. Once the driver is fully extracted, immediately measure its diameter with a tape measure, recording this essential specification for obtaining a properly sized replacement component.

Diagnosing the Specific Speaker Problem

Successful extraction of the damaged driver creates the opportunity for precise problem identification, which forms the backbone of any effective speaker repair. Visual inspection should first focus on physical damage indicators, including cone tears or separation from the rubber surround, as these issues often determine repair feasibility.

To test the speaker thoroughly, technicians should listen for distortion patterns—buzzing, crackling, or hissing—at higher volume levels, particularly focusing on frequency-specific anomalies. For definitive diagnosis, swapping the suspect driver with a functioning unit in a stereo setup can reveal performance disparities. A multimeter reading of the speaker’s impedance provides objective data to compare against manufacturer specifications, potentially identifying voice coil damage. During audio tests, manipulating equalizer settings while playing diverse musical selections helps isolate which driver component—tweeter, mid-range, or woofer—exhibits performance issues.

Cleaning and Preparing the Speaker Components

Proper cleaning of speaker components establishes the foundation for successful repairs, ensuring ideal adhesion and performance restoration. Before applying any new adhesive, technicians must meticulously remove old residue using a precision scraper, creating clean bonding surfaces. The speaker cone and surrounding elements require gentle cleaning with isopropyl alcohol on a lint-free cloth to eliminate contaminants that could impair sound quality or adhesion.

Following the initial cleaning, a thorough inspection helps identify any remaining debris or imperfections that might interfere with the speaker’s piston action. Precise measurements using a ruler confirm proper component alignment for reassembly. All cleaned surfaces must dry completely for 15-30 minutes in a dust-free environment, preventing moisture-related complications during subsequent adhesive application. This preparation phase, while often overlooked, directly influences the longevity and acoustic quality of the repair.

Repairing or Replacing the Speaker Cone

When a speaker’s audio quality deteriorates noticeably, examining the cone for damage becomes essential, as this component directly transforms electrical signals into the sound waves we hear. For small tears, rubber cement from bicycle tire patch kits provides an ideal flexible bond, allowing for future repairs while maintaining proper piston action. When attaching separated cones to their surrounds, Gorilla Glue creates a strong bond, though the adhesive must dry completely before testing.

If damage is extensive, replacement becomes necessary. Measure the speaker driver diameter precisely with a tape measure to verify compatibility with the original specifications. Remove the damaged driver by unscrewing mounting screws and disconnecting wires, then install the replacement by aligning screw holes carefully to prevent voice coil misalignment. After installation, test at low volumes to identify and resolve any buzzing issues.

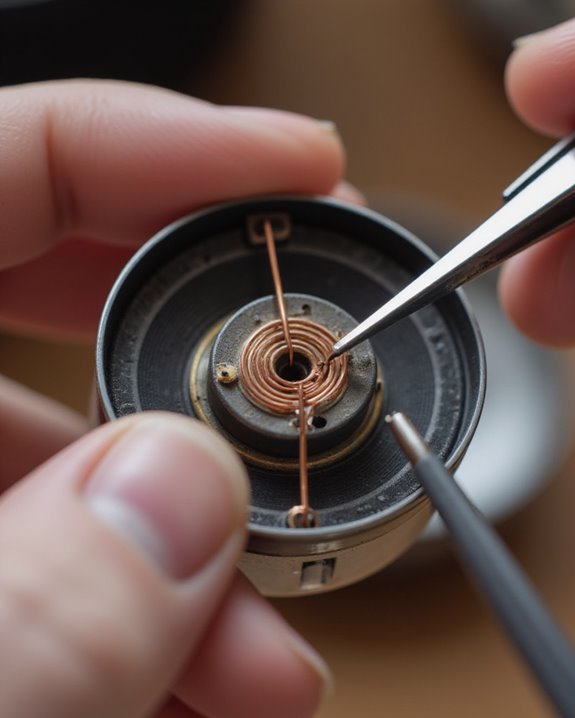

Reconnecting and Aligning the Voice Coil

Realigning the voice coil demands precision and careful attention to detail, as this delicate component forms the heart of any speaker system. When reconnecting, technicians must guarantee the coil remains centered within the magnetic gap to prevent scraping against surrounding structures, which could compromise sound quality. Inserting temporary spacers inside the voice coil during repair helps maintain proper alignment and protects sensitive components.

Before reconnection, all old adhesive residue should be thoroughly removed to create an ideal bonding surface. After the voice coil is secured, testing at low volume verifies proper alignment, as uneven tension will immediately manifest as distorted audio output. Many enthusiasts report successful repairs through careful resoldering techniques, with positive results observed in various speaker models including Advents and JBL units, demonstrating that proper voice coil reconnection can fully restore speaker functionality.

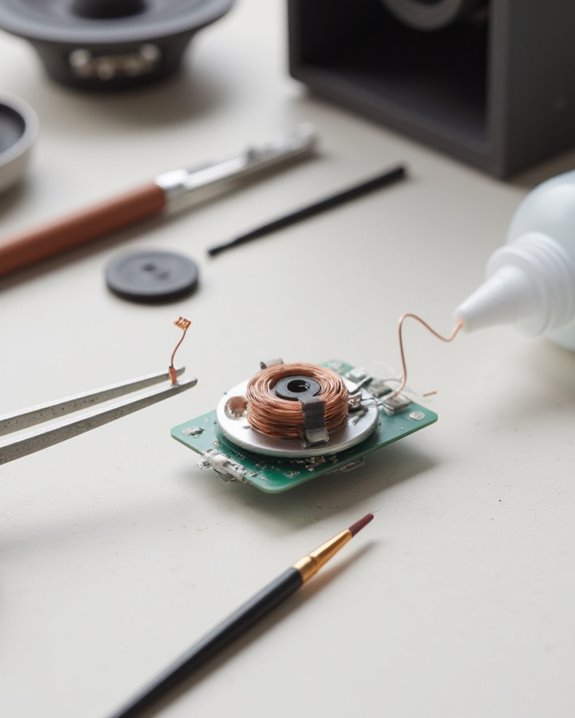

Applying Adhesive and Securing Components

Once the voice coil has been properly aligned, the next phase of speaker repair focuses on applying adhesive and securing the components for long-term durability. Technicians should first remove all traces of old adhesive from the speaker components using an appropriate tool, creating a clean surface for ideal bonding.

Gorilla Glue should be applied evenly along the rubber surround’s edge when reattaching it to the cone, as this adhesive is specifically formulated for rubber materials in speaker repair. Spacers must remain inside the voice coil during this process to maintain proper alignment within the gap. After applying adhesive, components should be secured by aligning with existing screw holes and fastening gently, avoiding over-tightening that could warp materials. The repaired speaker must then dry thoroughly for several hours in a dust-free environment before testing.

Allowing Proper Drying and Curing Time

Successful speaker repair depends greatly on allowing adequate time for adhesives to dry and cure completely. For small speaker repairs, particularly when reattaching rubber surrounds, adhesives should dry for a minimum of 24 hours or according to manufacturer specifications. This patience guarantees a strong, even bond that maintains proper voice coil alignment and prevents future damage.

During the curing process, technicians should maintain a dust-free environment, especially when using adhesives like Gorilla Glue, to achieve maximum bonding strength. Rushing this critical step often leads to uneven tension or off-axis attachment, which compromises the speaker’s piston action and overall sound quality. Technical experience shows that inadequate drying time is a primary cause of repair failures, as the voice coil may scrape against the magnet gap when the speaker operates, resulting in distortion or complete failure.

Testing and Reinstalling Your Repaired Speaker

Proper reinstallation represents the final critical phase in the speaker repair process, requiring attention to both physical mounting and electrical connections. When fitting the new driver into the speaker hole, technicians should position wires upward on the back of the component, connect them to their corresponding terminals, and secure the assembly with appropriate screws. After installation, the protective grill must be reattached to shield internal components from potential damage.

Testing should proceed methodically, beginning with audio playback at reduced volume to detect irregularities such as buzzing or distortion. Technicians can isolate frequency-specific issues by adjusting equalizer settings—increasing treble for tweeter assessment, mid-range for vocal clarity, or bass for woofer performance. If anomalies persist during evaluation, operators should verify screw tightness and driver alignment before retesting to confirm the repair’s success. For enhanced testing, incorporating EQ presets can help simulate various audio scenarios and fine-tune the speaker’s performance.

Frequently Asked Questions

How Can I Repair a Speaker?

Speaker repair involves diagnosing issues through visual inspection and sound testing, removing damaged drivers, selecting compatible replacements matching specifications, proper installation with correct wiring, and thorough testing. Speaker upgrades can enhance sound quality during repairs.

How to Make a Speaker Step by Step?

Against modern technology’s complexity, Speaker DIY offers simplicity. One can create a speaker by winding a voice coil, positioning it within a magnet, attaching a cone, and enclosing the assembly in a cabinet.

How Do You Fix a Small Tear in a Speaker?

To fix a small tear in a speaker, one should remove the driver, clean the damaged area, and apply rubber cement for tear patching. After allowing adequate drying time, testing at low volume guarantees proper repair completion.

How to Fix a Blown Speaker Without Replacing It?

Just as sound waves find their path, blown speakers can be restored through careful repair. One can reattach loose connections using proper soldering tips, apply adhesive to cone tears, and realign voice coils with spacers.